| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: ST-0059

Additional Info

Packaging: Wooden box Tito Fumigation-free boxes

Brand: sanland

Transportation: Ocean

Place of Origin: China

Certificate: ISO9001

HS Code: 84742090

Port: Dalian

Product Description

Gyratory Crusher Technical Product Comparison

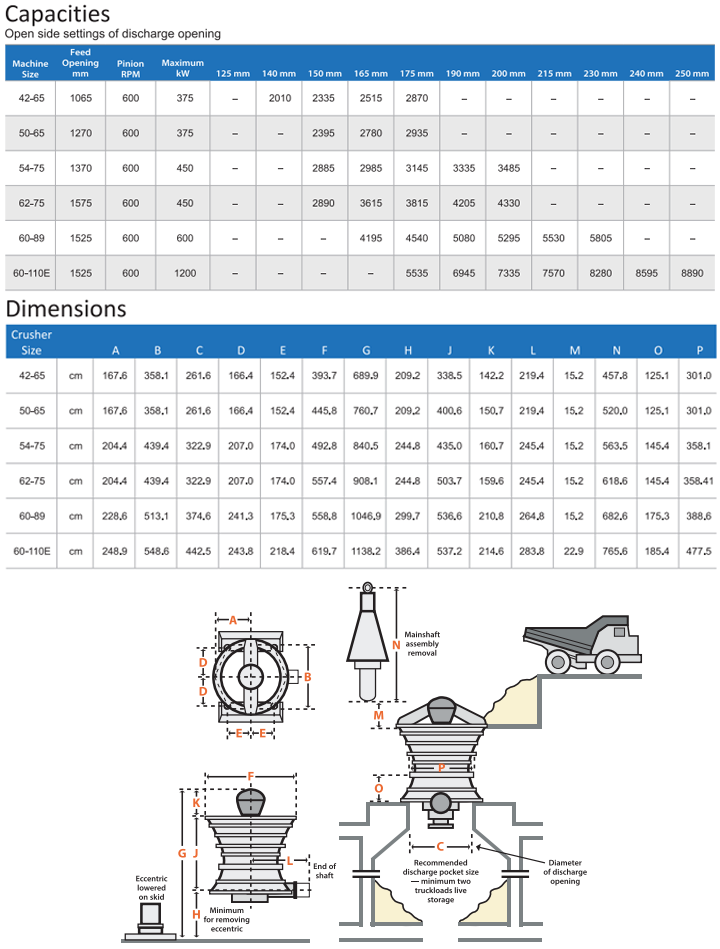

The design of the gyratory crusher and jaw gyratory crushers is based on more than one hundred years of experience. Primary gyratory crusher is designed for high throughput rates and high crushing ratios at low operating and maintenance costs.

Gyratory Crushing Equipment Design characteristics:

Spiral bevel gear toothing

Drive motors with heavy duty ratings

Heavy duty design

Optimized crushing chambers for direct feed

Crushing equipment has high throughput rates -Optimum crushing ratio

Change of stroke through adjustment of eccentricity

Direct drive for high starting torque facilitates start in case of emergency

Hydraulic main shaft adjustment for wear compensation and overload protection

Industrial crusher has low operating and maintenance costs

Features:

Crushing chambers are matched to each individual application, optimizing crushing performanceThe mainshaft position system provides easy adjustment of the mainshaft to compensate for liner wear and to control product size

© 2019 CHINA WAY. All Rights Reserved. Shenyang Sanland Mining Equipment Manufacture Co., Ltd., Inc. All rights reserved. site map. sitemap.html